Metal filters

for Plastics

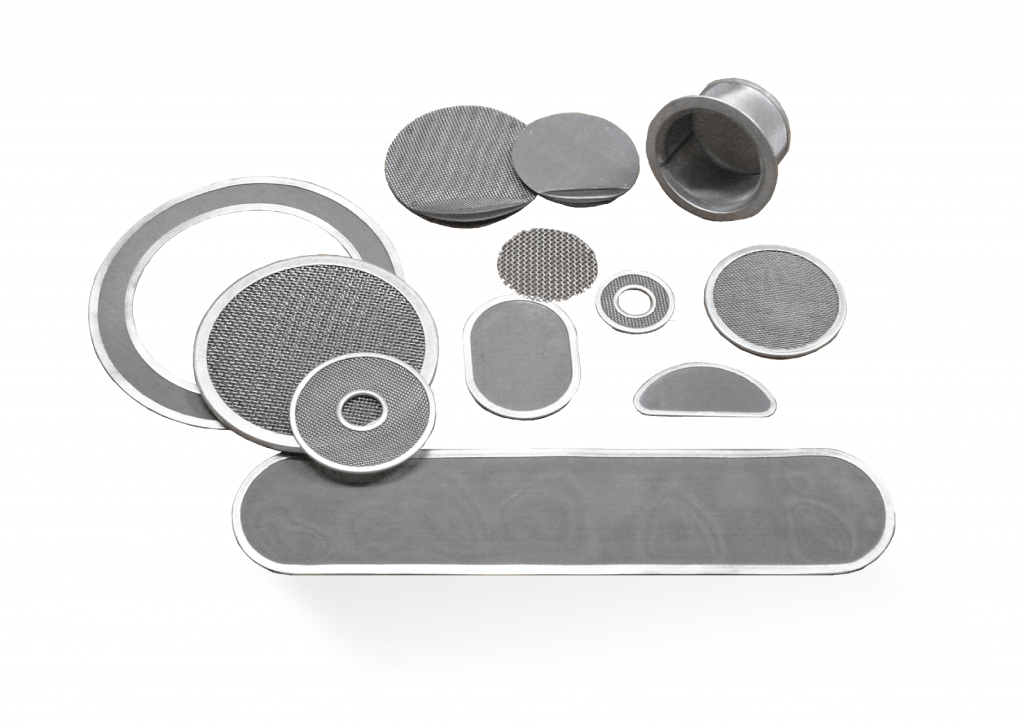

Profiltech, designs and manufactures filtering metal mesh packages through advanced manufacturing technologies, for use in plastic extrusion filtration processes.

Our filters have been approved, before the highest quality requirements in molten plastic processes by our clients. The use of Profiltech filters, guarantees a permanent consistency in the purity of your products.

Filtering parts are manufactured with different contours, designs and sizes, according to the requirements of your processes.

The filter packages can be manufactured with one or several layers of fabrics and different types of metal fabrics can be used in their formation.

Our filters for molten plastic mass have a high dimensional precision which guarantees a high performance in your productive processes with reduced waste.

Benefits:

![]()

High quality metallic fabrics, which exceed the tolerances of the international standard standards. Guaranteeing permanent uniformity in the quality of the contaminants retained.

![]()

Highly robust design, which provides high stability to the process, counteracting the high pressures, tensions and temperatures of the systems.

![]()

Combination of specialized metallic tissues, achieving high permeability structures and consistent structure. Suitable for backflow washing equipment.

![]()

High quality stainless steels, guarantee the elastic stability of filaments in metal fabrics, during the entire filtration process.

Metalic Filter Media

- Twilled dutch weave

- High flow dutch weave

- Robusta

- Duplex

- Plain dutch weave

- Sintered multilayer filter media type A

- Sintered multilayer filter media type B

- Sintered multilayer filter media type C

- Sintered multilayer filter media type D

- Sintered multilayer filter media type E

- Non woven filter media type A

- Non woven filter media type B

- Square mesh

If you have any suggestions or concerns, we are available to address them. Let us know how we can help you.