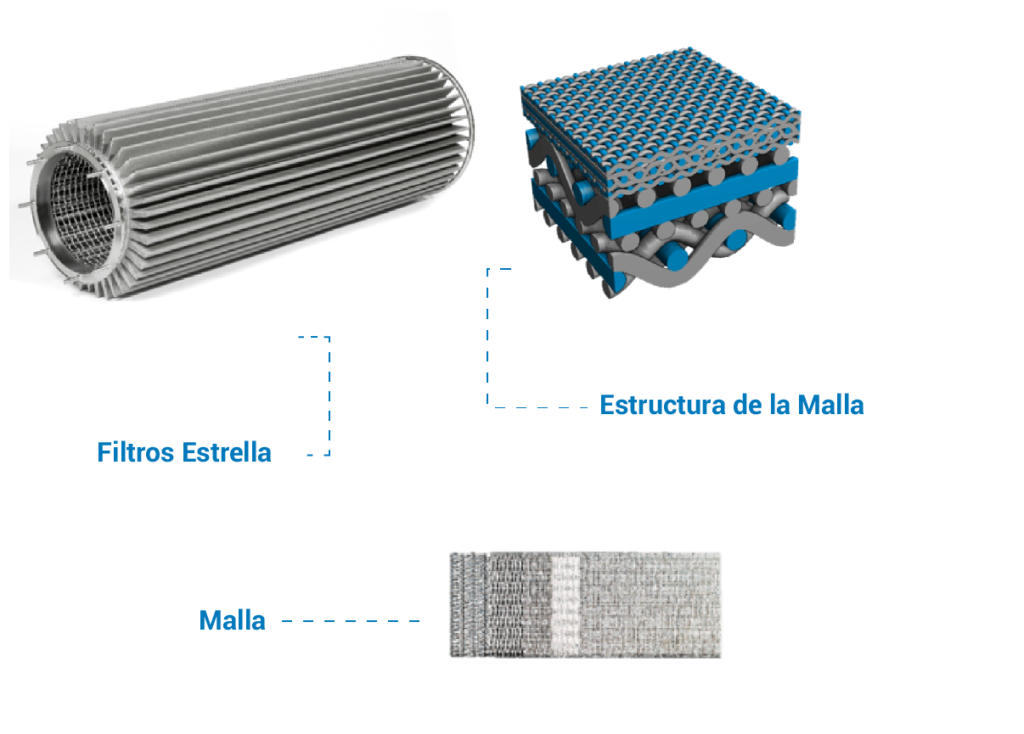

Multi Layer

Filter Media

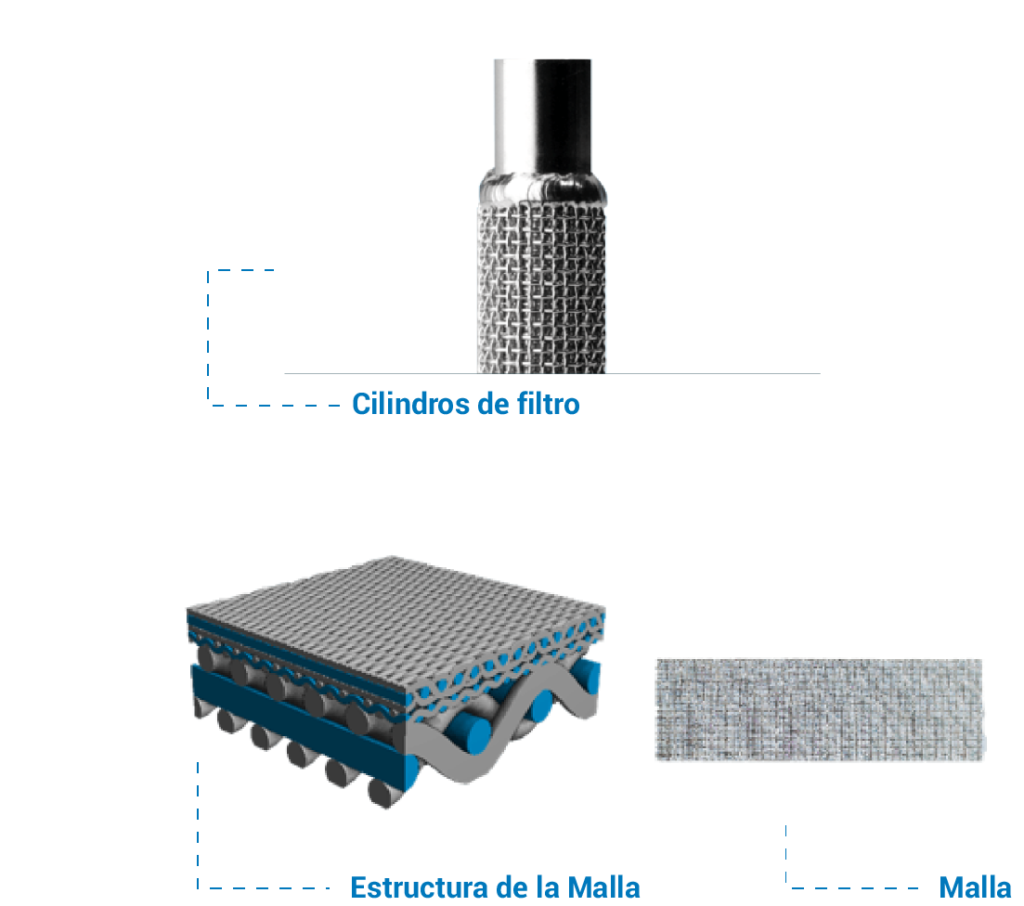

For challenging applications in filtration, sintered steel meshes are now increasingly used instead of filter meshes. Here, a selected range of meshes are bonded together using heat and pressure. This effectively combines the performance advantages of each individual mesh layer and results in optimization of the filtration process. The resultant bonded mesh enables the finest filtration to be achieved, but thanks to the robust mesh structure, the medium is resistant to physical loading. The smooth surface also offers advantages for the cleaning process when backwashing.

Properties and Advantages

Stainless steel filter meshes utilized by Delasierra integrate a number of important characteristics.

![]()

Defined finest aperture size and regular pore distribution

![]()

Optimum backwashing capability, advanced reliability in terms of backwashing pressure.

![]()

Extremely robust, resistant to mechanical and thermal loading (up to 600oC dependent upon alloy), long service life, therefore reduced downtime.

![]()

Consistent product quality, advanced levels of corrosion resistance with the use of noble metals such as stainless steel, Hastelloy, Inconel etc.

![]()

High flow rates, selectable flow resistance.

![]()

Reduced loading of the filter medium in pulsation.

![]()

Wide range of combinations up 1000 layers possible

![]()

Advanced reliability

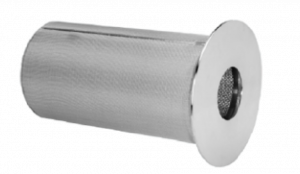

Sintered Multilayer Filter Media Type A

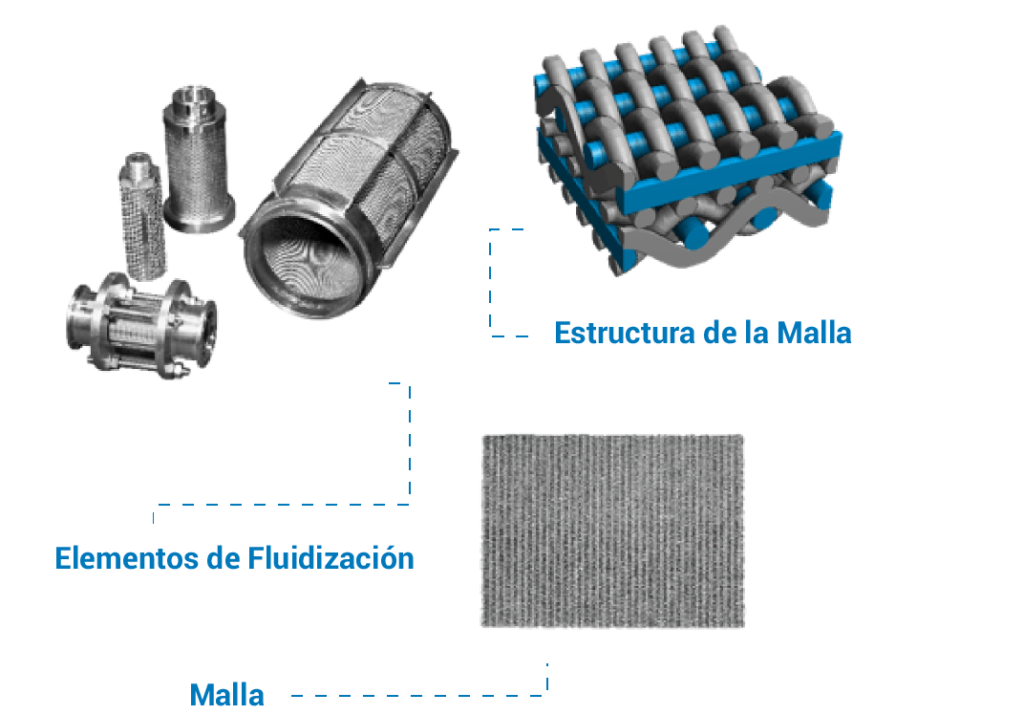

For monofilaments, a twilled dutch mesh weave produces the smallest pores and a smooth mesh surface, whilst the larger material cross section gives higher levels of mesh stability. When passing through a twilled dutch mesh, the particles must negotiate five offset pore levels. This means that oblong, thin, rod-shaped and fibrous particles are securely retained. Fine specification twilled meshes are used for fine filtration such as pressure filtration in hydraulic steering equipment and fuel filters for critical applications. Coarser specification twilled dutch meshes are used for pressure and vacuum filtration (disc, cell and drum filters) and as a porous medium for fluidised bed applications. These meshes are usually manufactured from stainless steel. These meshes have a slightly textured surface and are particularly useful for high flow.

Materials

![]() AISI 316L, AISI 904L

AISI 316L, AISI 904L

![]() Hastelloy alloys

Hastelloy alloys

![]()

Other materials available on request

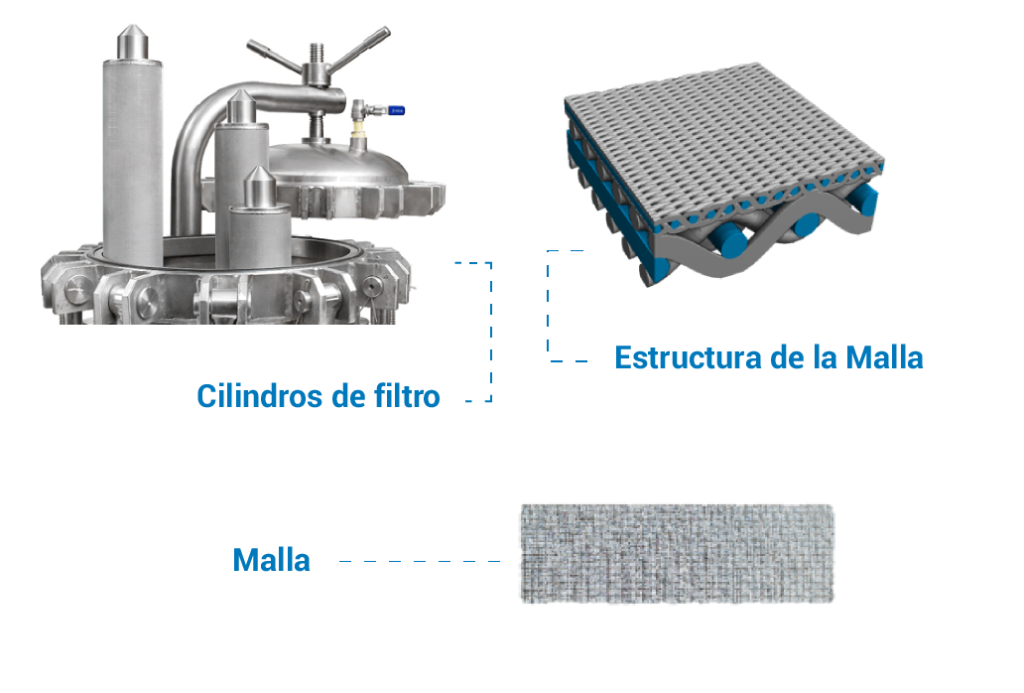

Application Recommendations

Filtration of highly viscous liquids: Nutsche filters, centrifuges, fluidised beds, aeration of silos, applications in biotechnology.

Absolute filter fineness: 5 –120 microns

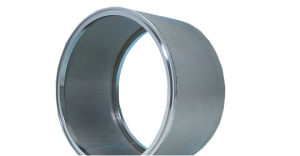

Sintered Multilayer Filter Media Type B

In contrast to TYPE A, TYPE B is a highly porous filter medium developed to achieve increased flow rates at moderate pressures. TYPE B is particularly useful for its cleanability and backwashing capabilities. TYPE B is also available in a five-layer structure with a reduced thickness of 1.7 mm-1.8 mm.

Materials

![]()

AISI 316L, AISI 904L

![]()

Hastelloy alloys

![]()

Other materials available on request

Application Recommendations

Optimum flow rates and backwashing properties make the TYPE B ideal for applications in liquid and gas filtration.

Absolute filter fineness: 15–90 microns

Absolute filter fineness: 5 –120 microns

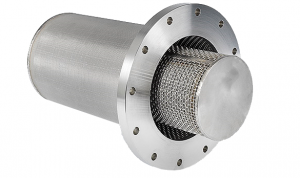

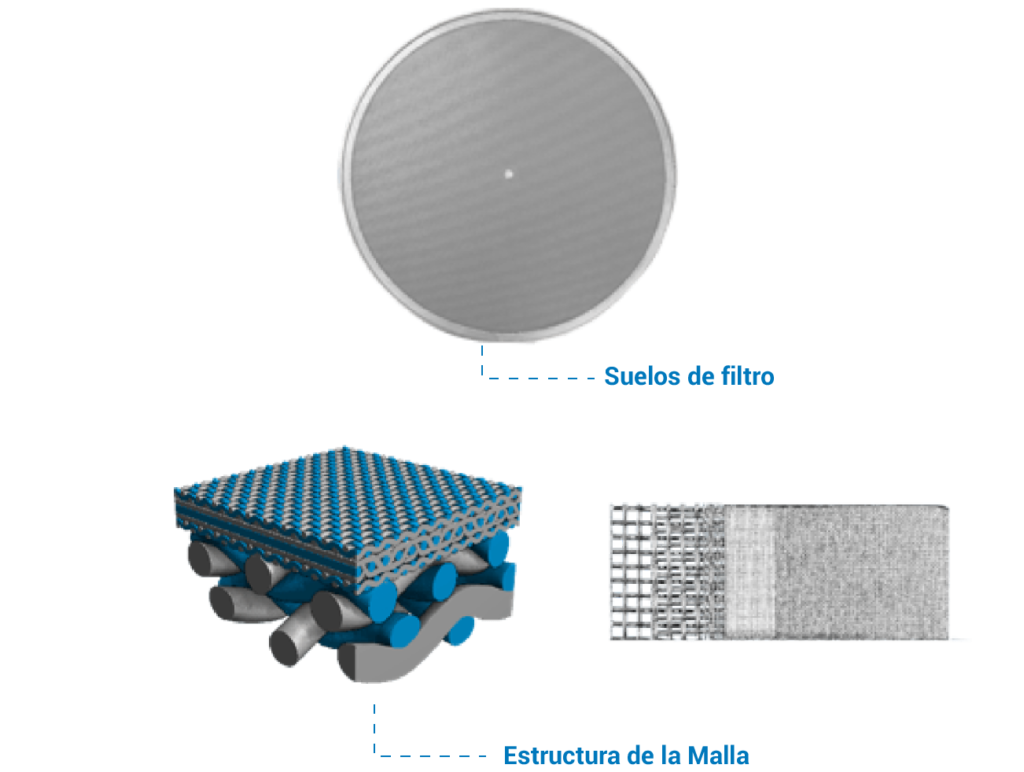

Robusta

TYPE C was developed to compensate for the reduced rigidity of fine filter cloths. Combining a filter cloth with a square weave support mesh provides stability at moderate pressures combined with good backwashing properties. A minimal number of layers means reduced pressure loss combined with effective backwashing. TYPE C is therefore ideal for CIP (Cleaning in Place) filters in the pharmaceutical industry. For applications where high pressure loads and larger diameter units are used, additional support media will be required.

Application Recommendations

Filters for the separation of separate solids and liquids, surface filtration for particulate separation, sieve plates, aeration filters, hydraulic filters, backwashing filters (also automated), cleaning baskets for small components.

Absolute filter fineness: 10 – 530 microns.

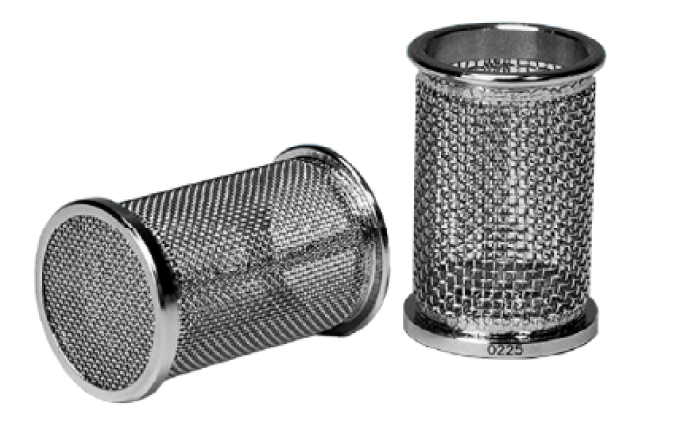

Sintered Multilayer Filter Media Type D

In comparison with TYPE C, this laminate features an additional bonded layer between the filter mesh and the square weave support mesh. Constant low flow resistance and good backwashing capabilities enable higher pressure loads to be handled. TYPE D is particularly suitable for use with CIP (Cleaning In Place) filters.

Application Recommendations

As TYPE C as well as for sturdy aeration filters, Nutsche filter floors, spray driers, drying plant, container baskets for cleaning plant and filter drums for coolant lubrication equipment.

Absolute filter fineness: 10 – 530 microns

Sintered Multilayer Filter Media Type E

Type E is a two- or three-layer laminate featuring offset layers of twilled wire cloth. The resultant thickening of the surface changes the laminate into a highly stable, air permeable metallic membrane with reduced porosity. TYPE E is particularly suitable for applications where high levels of flow resistance are required.

Application Recommendations

Fluidisation elements, fluidised bed floors, aeration elements, pneumatic conveyor

troughs.

If you have any suggestions or concerns, we are available to address them. Let us know how we can help you.