Paper and Cellulose

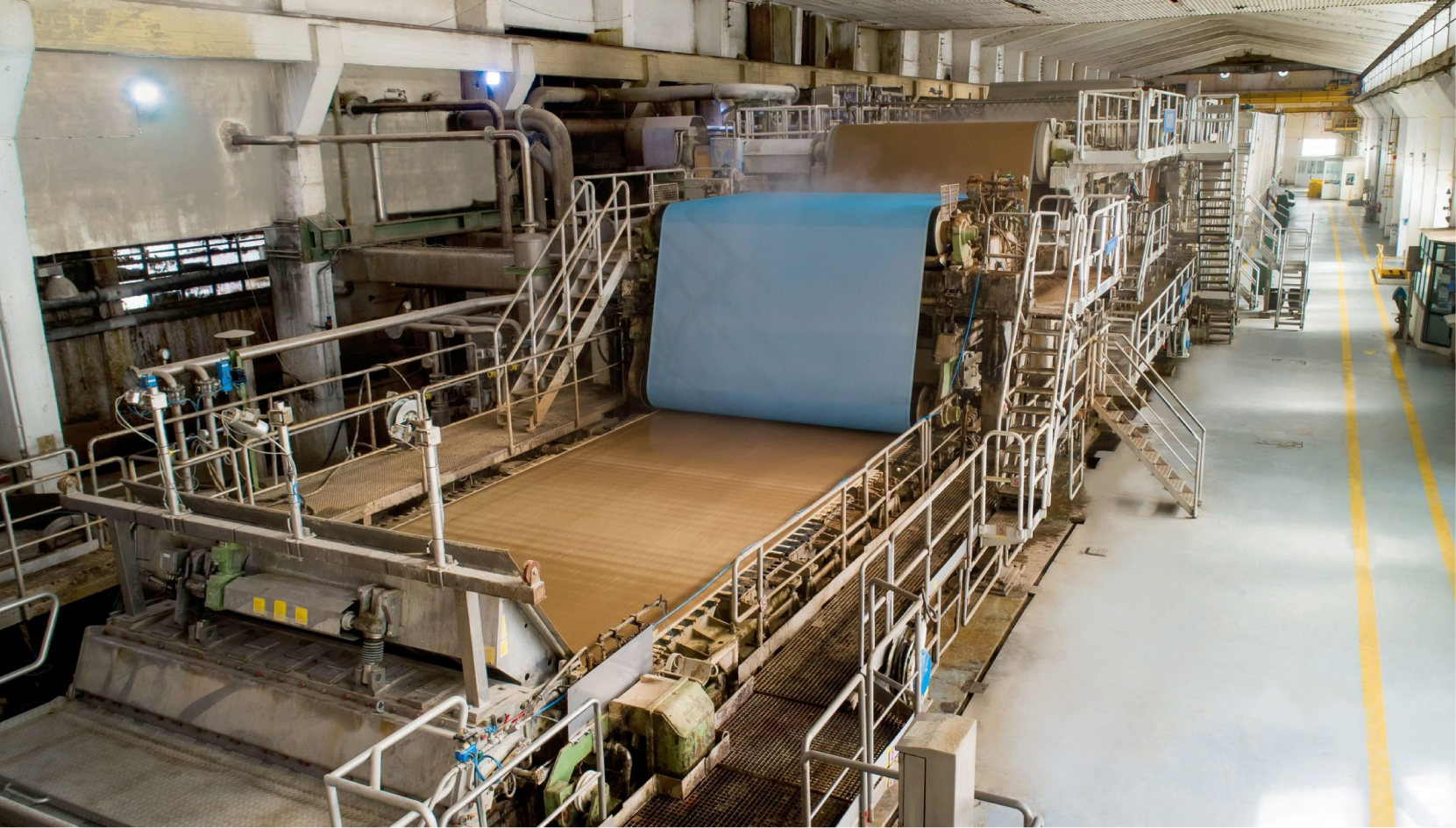

Papermaking is effectively a filtration operation: a suspension of cellulose fibers is sprayed onto a filter medium (the wire) and drained to an acceptable solid content before being pressed to increase its dryness prior to thermal drying. Although not generally considered a filtration process, papermaking involves other filters and separators, and your product is one of the primary materials used for filter media.

There are ongoing needs for improvement in water quality for recycling and emissions reduction in the paper and board manufacturing sector, but the greatest need for improvement probably lies in the development of better flotation methods for recycled paper destination.

Applications:

![]() Removal of sand from river water

Removal of sand from river water

![]()

Algae removal from pond water

![]() Sand filter replacement

Sand filter replacement

![]() Process water recycling

Process water recycling

![]() Cooling water for compressors

Cooling water for compressors

![]() Final improvement of wastewater before discharge

Final improvement of wastewater before discharge

![]() Water filtration from float

Water filtration from float

![]() Patina Filtration

Patina Filtration

![]() Discharge water filtration to the outside

Discharge water filtration to the outside

![]() Water filtration from well, river

Water filtration from well, river

![]() Cooling towers: Full flow or side mounted

Cooling towers: Full flow or side mounted

![]() Pulp, paper and cardboard manufacturing

Pulp, paper and cardboard manufacturing

![]() Manufacture of paper and cardboard articles

Manufacture of paper and cardboard articles

![]() Publication, printing and reproduction of recorded media

Publication, printing and reproduction of recorded media