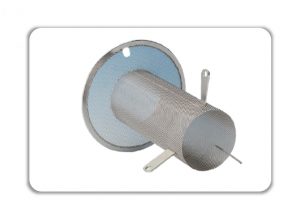

Single Layer

Filter Meshes

The raw materials of woven filter medium produced by our manufacturers are available in a comprehensive and diverse range of medium, fine and ultrafine filter meshes. These are produced using state of the art weaving machines, in clean and air-conditioned halls, to the highest levels of quality and reproducibility. Dependent upon requirements, we convert the meshes into dimensionally accurate components and semi-finished goods, with individual items carefully worked by hand and series production either partly or fully automated using special machinery designed expressly for this purpose.

Benefits:

Stainless steel filter meshes utilized by Profiltech integrate a number of important characteristics.

![]()

Optimum flow rates

![]()

Precise aperture size distribution

![]()

High levels of stability

![]()

Rigidity

![]()

Advanced abrasion resistance

![]()

No particle detachment

![]()

Easy to clean

![]()

Good plasticity

![]()

Chemical and thermal resistance

![]()

Smooth surface structure

![]()

Advanced reliability

Availability:

![]()

Mostly produced using stainless steel AISI 304L, and AISI 316 L, sometimes using other alloys such as monel, Hastelloy, AISI 904 L, Titanium etc.

![]()

Bespoke specifications also available

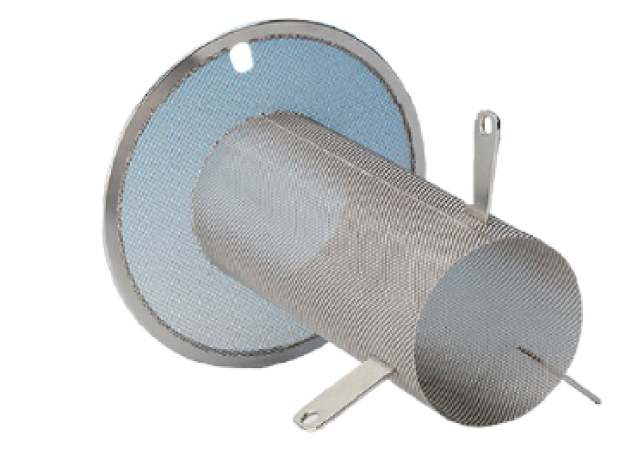

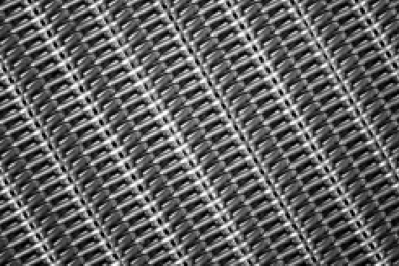

Twilled Dutch Weave

This lead-like filter medium consists of five different wire cloth layers, put together so precisely that they achieve the optimum combination of stability, filter fineness, flow rate and backwashing properties. TYPE A is particularly suitable for fine and finest filtration applications at high pressures and harsh operating environments.

Materials

![]() AISI 304L, AISI 316L, AISI 904

AISI 304L, AISI 316L, AISI 904

![]() DIN 2.4602 / Hastelloy C22

DIN 2.4602 / Hastelloy C22

![]()

Other Materials on request.

![]()

Absolute filter fineness: 6 – 166 microns

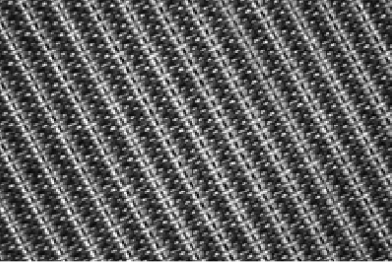

High Flow

High Flow is a further development from plain weave mesh. In comparison to the standard plain weave, it has a greater pore count, and the pores on the surface are smaller than the inner pores. The mesh therefore achieves higher flow rates and greater dirt removal capabilities, and also features exceptional backwashing performance. These meshes are generally used for oil and fuel systems, subject to higher levels of contamination, and also to protect steering and fuel injection jets as well as friction bearings.

Materials

![]()

AISI 304L, AISI 316L, AISI 904L

![]()

DIN 2.4602 / Hastelloy C22

![]()

Other Materials on request.

![]()

Absolute filter fineness: 15 – 90 microns

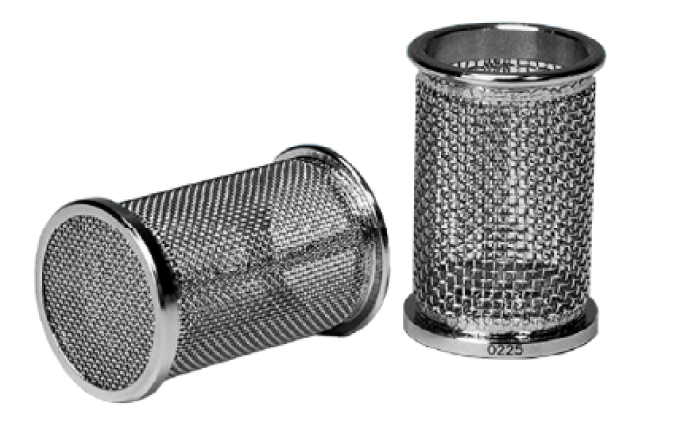

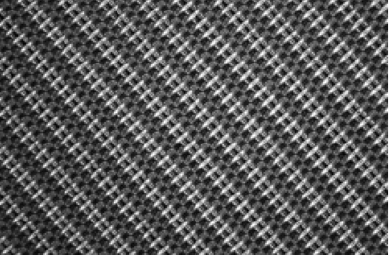

Sintered Multilayer Filter Media Type C

Thanks to higher levels of porosity, this mesh can withstand particularly high flow rates. A regular cross section in both warp and weft directions facilitates the highest mechanical loadings. These robust meshes are used for settling filters, filter candles, vacuum filters and well filters.

Materials

![]()

AISI 304L, AISI 316L, AISI 904L

![]()

DIN 2.4602 / Hastelloy C22

![]()

Other Materials on request.

![]()

Absolute filter fineness: 17 – 175 microns

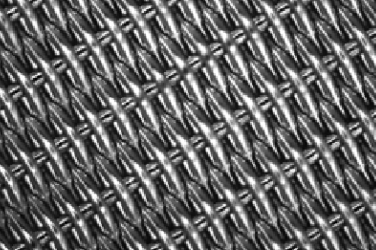

Duplex

These meshes also achieve high flow rates and can withstand high mechanical loadings. Duplex meshes are the preferred choice for applications such as pressure and vacuum filters, as well as filter candles.

Materials

![]()

AISI 304L, AISI 316L, AISI 904L

![]()

DIN 2.4602 / Hastelloy C22

![]()

Other Materials on request.

![]()

Absolute filter fineness: 19 –112 microns

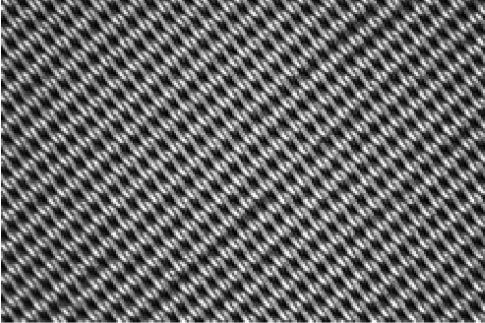

Plain Dutch Weave

These meshes have a slightly textured surface and are particularly useful for high flow rates and low-pressure loss. They are used where mechanical loading is increased, such as for settling filters and filter candles.

Materials

![]()

AISI 304L, AISI 316L, AISI 904L

![]()

DIN 2.4602 / Hastelloy C22

![]()

Other Materials on request.

![]()

Absolute filter fineness: 45 – 306 microns

If you have any suggestions or concerns, we are available to address them. Let us know how we can help you.